Our Expertise

Our seasoned team of Consultants and Engineers, with international expertise, deliver comprehensive support to the railway infrastructure industry across track components and business fields.

What we do

Track data acquisition

and management for design and implementation of enhanced, 360° predictive rail maintenance strategy

Track data acquisition

and management for design and implementation of enhanced, 360° predictive rail maintenance strategy

Track data management

through Business Intelligence using your existing software or commercial off-the-shelf software solutions

Track data management

through Business Intelligence using your existing software or commercial off-the-shelf software solutions

Digital transformation & Automation

Design and implementation of strategies and tools for track infrastructure asset management

Digital transformation & Automation

Design and implementation of strategies and tools for track infrastructure asset management

Wheel-rail interface analysis

to improve safety, riding comfort and life-cycle costs of wheel/rail

Wheel-rail interface analysis

to improve safety, riding comfort and life-cycle costs of wheel/rail

End-to-End track asset management

as a service for individual assets or even full scope

End-to-End track asset management

as a service for individual assets or even full scope

Turnout management

through the use of specific algorithms

Turnout management

through the use of specific algorithms

Technical audits

focused on sustainable use of environmentally friendly technologies and asset management procedures

Technical audits

focused on sustainable use of environmentally friendly technologies and asset management procedures

Ballast and subgrade management

based on your existing, recorded data

Ballast and subgrade management

based on your existing, recorded data

Root cause analysis

of recurring defects, early degradation, unsafe conditions of relevant assets of your track infrastructure

Root cause analysis

of recurring defects, early degradation, unsafe conditions of relevant assets of your track infrastructure

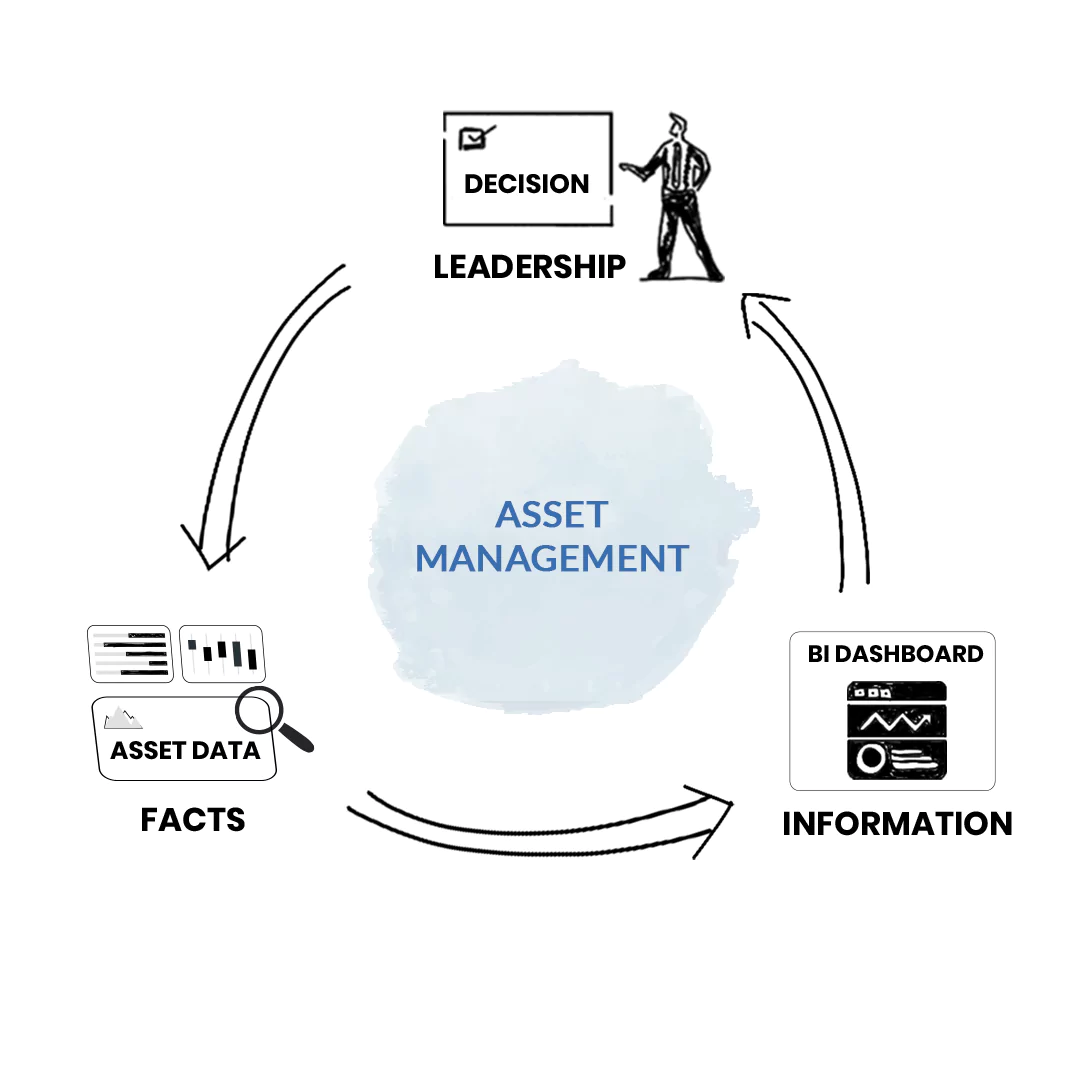

We do things differently

Our international consulting experts combine hundreds of years of track optimization experience with Business Intelligence tools to deliver sustainable information to you, useful for the problem at hand as well as for future decision making.

The Global Rail Group Advantage

- Industry experts : A team of experienced, former track infrastructure technical managers, with on-the-job experience, bringing you first-hand expertise

- Diverse perspectives : Balanced team of seasoned and young talent, ensuring a holistic perspective in all our solutions

- International team : An international team, allowing us to bring global expertise & experiences to the table

- Integrated Approach : Integrating railway specific knowledge with Business Intelligence to deliver sustainable solutions, in any specific environment

- Motivated by the success of railway : Empowering you by transferring knowledge that makes a long-term impact, rather than only sharing information to solve short-term problems

- Partners, not consultants : We are your partners who solve problems and develop solutions efficiently and using each other’s collective strengths

- Partner network : Wide & global network of partners and experts that help us execute global tactics & ideas in a local context

Meet the team

Jan Mys

Adam Sohasky

Klaus Liebwald

Andreas Oberhauser

Frank Buchmann

Albert Hayr

Elena Crespo Domingo

Roger Campbell

Kathrin Gabert

Teever Handal

Raphael Marotta

Xavier Rodriguez Somoza

Pablo Merayo

Brad Kerchof

Jack Lindquist

Allen Pierson

Jeff Schweisthal

Sean Regehr

Casslynn Ennis

Henry Kweens

Shane Kweens

Steve Gainey

George Senterfitt III

Beatriz Alonso Vázquez

Zsolt Hörcsik

Alberto Pérez Carabias

Jan Mys

Work Experience

Global Rail Group since 2021

2020-2021 Infrabel, Head of Budgeting & General Manager

2018-2020 Infrabel, Deputy Director Asset Management & General Manager

2014-2019 Infrabel, Head of Simgular Assets

Education

MBA Vlerick School of Management,

Ughent

Civil Engineering Electro-mechanics Energyconversion

Languages

English

Dutch

French

German

Positions

ERA speaker for Conventional Rail TSI

CEN / CENELEC – Subgroup convener for working groups / TC256 SC1 secretary

Adam Sohasky

Work Experience

Sep 2023 – Present: Global Rail North America – Senior Technical & Business Development officer

July 2022 – Sep 2023: Canadian National Railway Company – Senior Manager Rail & Testing

April 2017 – July 2022: Canadian National Railway Company – Manager Rail & Testing

April 2013 – Apr 2017: Canadian National Railway Company – Field Engineer April

June 2012 – June 2009; Canadian National Railway Company – Civil Engineering Intern: Apr 2008 – Sep 2008

Education

Bachelor of Science – BS Civil Engineering Michigan Technological University

Languages

English

German

Publications

Laboratory Evaluation of Gage Face Lubricants Using Disc-on-Disc Testing Mark D. Richards, PhD, EVRAZ NA and Adam Sohasky, Canadian National Railroad

Positions

University lecturer for “Railway Maintenance” (Vienna University of Technology);

University lecturer for “Life cycle management and predictive maintenance” (St. Pölten University of Applied Sciences)

Memberships

AREMA Committee 4 Subcommittee 4

Friction Management, 8

Nondestructive Testing of Rail & 9

Railway, Grinding & Lubrication Michigan Technological University Rail Transportation Advisory Board, Vice Chair

Klaus Liebwald

Work Experience

2023 – : Expert for infrastructure maintenance strategies; Interface Management (Global Rail Group)

2019 – 2023: Consultant Expert for operation and maintenance (DB Engineering & Consulting GmbH)

2012 – 2019: Specialist for track planning; technical consultant; specialist asset management (ÖBB)

1997 – 2012: Apprenticeship as mechanic (ÖBB); Journeyman track construction (ÖBB)

Education

Diploma in Industrial Engineering and Management (HTL-TGM

Railway- and civil engineering diploma (ÖBB)

Languages

Deutsch

English

Andreas Oberhauser

Work Experience

Since 2021: Senior Manager at Global Rail Consulting and Knowledge Manager for Global Rail Group

2018 – 2021: Head of Department Track Infrastructure at Wiener Linien

2011 – 2018: Head of Staff Unit Infrastructure Inspection at Wiener Linien

2007 – 2011: Maintenance Process Manager Track at Wiener Linien

2003 – 2007: Research Fellow at Vienna University of Technology (TU Wien)

Education

Dr. techn. (Ph.D.) in civil engineering; TU Wien

Languages

German

English

Italian

Publications

Stuart L Grassie, Andreas Oberhauser, Michael Ostermann, Bernhard Hinterndorfer, Werner Wehr, Philip Ali: Monitoring, understanding and maintenance of rail defects on a European metro system; 12th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems (CM2022), Melbourne, Australia, 4-7 September, 2022;

M. Fracchia, R. Carlson, P. Steckler, A. Oberhauser, N. Leitao: Enhance the Environmental Performance of Railway Infrastructure; Procedia

Social and Behavioral Sciences

Positions

University lecturer for “Railway Maintenance” (Vienna University of Technology);

University lecturer for “Life cycle management and predictive maintenance” (St. Pölten University of Applied Sciences)

Memberships

CEN TC 256 SC1 WG18 DG15 Urban Rail Switches and Crossings;

CEN/CENELEC – Member of the Urban Rail Survey Group within the mandate M/486 of the European Commission;

Forschungsgesellschaft Straße – Schiene – Verkehr (FSV): Work Group Leader AA EB13 „Regional railways“

Awards

Federal Transport Award 2008 (“Staatspreis Verkehr 2008“) for Research project “Energy systems for TunnelThermics®“ for TU Wien and Wiener Linien;

Professor Julius Kar-Award for excellent studies at

BOKU Vienna

Frank Buchmann

Work Experience

Since 2023: Senior Expert of Global Certifications and Regulations for Global Rail Group

2020 – 2023: Head of Department “Train running simulation and trafficability studies” at Deutsche Bahn, DB Netz AG

2011 – 2020: Head of Department “Running Dynamics/Tonnage Rating Calculation” at Deutsche Bahn, DB Netz AG

2010 – 2017: CER Speaker for TSI Infrastructure, CER (Community of European Railway and Infrastructure Companies)

2007 – 2011: Interoperability Expert at Deutsche Bahn, DB Netz AG

2004 – 2005: Supervisor Installation, Taiwan Shinkansen Trackwork Joint Venture (TSTJV) on behalf of Deutsche Bahn AG and Pfleiderer Track Systems (today RAIL.ONE GmbH)

2002 – 2006: Consulting Engineer Track and Rules at Deutsche Bahn, DB Systemtechnik GmbH

2001 – 2002: Project-Engineer at Spiekermann GmbH Consulting Engineers

Education

Dresden University of Technology

Dipl.-Bauing. (TU), Civil Engineering

Languages

German

English

Publications

Bahnwesen, 6. Auflage (Kapitel 3 Trassierungselemente)Bahnwesen, 6. Auflage (Kapitel 3 Trassierungselemente), Werner Verlag, 2011 Das Infrastrukturregister der DB AG, EI – DER EISENBAHNINGENIEUR | Ausgabe 05/2009, DVV Media Group GmbH Grenzlastberechnung bei der DB Netz AG, EI – DER EISENBAHNINGENIEUR | Ausgabe 04/2018, DVV Media Group GmbH GretA: Der GrenzlastAnzeiger der DB Netz AG, Deine Bahn 10/2020, Bahn Fachverlag GmbH Handbuch – Das System Bahn, 3. Auflage (Kapitel 7.2 – Fahrdynamik der Zugfahrt), PMC Media House GmbH, 2021=> [https://www.trackomedia.com/programm/rail/427/handbuch-das-system-bahn?c=5]

Albert Hayr

Work Experience

Since October 2022: Senior Expert IT, Cloud, Software and Data Architecture at Global Rail Group in Vienna

Since 2010: Freelance consultant in the area of IT, Cloud, Software and Data Architecture and especial Open Source license compliance and quality assurance

2019-2022: Senior Expert IT, Cloud, Software and Data Architecture and Open Source at Kapsch TrafficCom responsible for group wide guidance and governance

2016 – 2019: Senior Expert Software and System Architecture at Kapsch PublicTransportCom responsible for the development and operation mobile apps and IoT portfolio

2012 – 2016: Senior Expert Software and System Architecture at Kapsch CarrierCom as chief architect for a GSM-R platfrom development

2003 – 2012: Expert and Solution Architect for voice and data services at Kapsch CarrierCom

1995 – 2003: Field engineer for voice services at Kapsch CarrierCom

Languages

German

English

Elena Crespo Domingo

Work Experience

Since January 2023: Manager at Global Rail Consulting

2021 – 2022: Senior Consultant at Global Rail Consulting

2018 – 2021: Innovation Project Engineer Plasser & Theurer Export von Bahnbaumaschinen G.m.b.H.

2017 – 2018: Junior Signalling Project Engineer at INECO

Education

MSc Mechanical Engineering

Universidad Politécnica de Madrid (UPM)

Languages

English

Spanish

German

Roger Campbell

Work Experience

Since 2022: Senior Consultant at Global Rail Consulting

2021 – 2022: Railway Track Coordinator in the Rail Baltic Project at IDOM

2020 – 2021: Track Engineering Department at ADIF Argentina.

2017 – 2020: Senior Consultant of large-scale projects at ACyA (Transport Engineerin Company)

Education

Msc. Civil Engineering

Universidad Tecnologica Nacional (UTN)

Languages

Spanish

English

Kathrin Gabert

Work Experience

Since Sept. 2021: Senior Consultant at Global Rail Consulting

2014-2021: Consultant at Verkehrsplaner GmbH

2011-2013: Junior Consultant at Traffix Verkehrsplanung GmbH

Education

Magister of Business Administration from Vienna University of Economics

Languages

German

English

Teever Handal

Teever has more than 38 years working experience in the rail industry. He spent 11 years with the Association of American Railroads at the Transportation Test Center helping develop vehicle dynamic simulation software, performing vehicle/track interaction and wheel/rail interaction research. He worked for a Progressive Rail Technologies providing truck performance and wheel impact detectors, and consulting on derailment analysis and vehicle/track interaction studies. Since 2014 Teever has been working for ARM in data analysis, as a wheel/rail interaction specialist, and technical expert in vehicle/track interaction. During his career he has provided assistance to clients in North America, Europe, Australia, Brazil, and India.

Raphael Marotta

More than 12 years of experience within Heavy Haul Railways, covering positions such as Railway Expert and Senior Engineer being responsible for vehicle/track interaction , track geometry monitoring as well as maintenance strategy. He also gives lectures at IPOG and is a researcher at Instituto Militar de Engenharia. Raphael joined Global Rail Group in 2023.

Xavier Rodriguez Somoza

Work Experience

Since 2022: Senior Consultant at Global Rail Consulting

2019 – 2022: O&M Engineer in charge of the maintenance phase of Liège Tramway PPP turnkey project at CAF

2012 – 2019: Track Maintenance and Works Manager for commuter, metro and tramway lines at RATP

2009 – 2012: Site Engineer at HSR project in Spain at Puentes y Calzadas Infraestructuras (civil engineering contractor)

Education

Msc. Civil Engineering

Universidad de A Coruña

Languages

Spanish

English

French

Portuguese

Italian

Pablo Merayo

Work Experience

Global Rail Group (April 2023 – present)

Consultant focused on overhead lines

TRN Táryet (September 2020 – April 2023)

Development of linear infrastructure projects

Data analysis

Field works

Tendering, among others

C. & G. Carandini (May 2018 – July 2019)

Development of lighting projects (outdoor lighting and tunnels)

Analysis of new optics for possible product developments

Education

Msc. Civil Engineering (Urban transports)

Universidad Politécnica de Madrid (UPM)

Technische Universität München (TUM)

Language

Spanish

English

Brad Kerchof

Brad is currently working part-time for ARM/Global Rail Group with the emphasis on projects involving track maintenance and inspection and brings 42 years of work experience with two Class 1 railroads – Conrail and Norfolk Southern. His first 32 years were with Maintenance-of-Way, including assignments like Division Engineer in Indianapolis, Pittsburgh and Birmingham, where he was responsible for track and bridge inspection, maintenance and development of capital programs. During his last 10 years with NS, he served as the Director of Research & Tests (track geometry testing, derailment investigation, wheel-rail performance research, mechanical and track failure analysis and materials testing).

Since 2012 he has been an annual presenter at the Wheel-Rail Interface conference.

Jack Lindquist

Jack Lindquist has a wealth of practical rail experience, spanning over 40 years. His work with ARM is primarily concerned with all quality issues related to rail profile grinding practices.

As a welder foreman, Jack was responsible for all aspects of project – scheduling, team training, quality control, troubleshooting and problem resolution, and contractor relations. In addition, his extensive background in heavy equipment operation provides the ARM team with a high level of expertise in operational safety of different types of large equipment.

ARM makes extensive use of his skills and experience as Senior Rail Maintenance Specialist. He is responsible for oversight of rail profile grinding operations, as well as implementing new wheel and rail profile maintenance and repair techniques incorporating the use of range vision (laser strobe and camera) optical measurement systems.

Allen Pierson

Allen has been a member of AWS for 45 years and a member of Arema Committee 4 for 40 years. He has Certified AWS railroader welding practices, is an AWS visual weld inspector,and works as a Level 2 UT operator. For 40 years he worked on 3 railroads Penn Central Conrail Norfolk Southern. Allen is a welder instructor for ARM since 2014.

Jeff Schweisthal

Before joining ARM, Jeff worked for Loram Maintenance of Way Inc. for 15 years, operating and maintaining rail grinding equipment. Since joining ARM in 2005, he has managed turnkey rail grinding programs on many transit systems including San Jose (VTA), San Diego (Trolley), Edmonton Transit, Dallas (Trinity Railway Express), Boston (MBTA), SCRRA/Metrolink, BART, and others. His background in the operations and maintenance of rail grinding equipment enables him to determine the capabilities and assess the performance of various grinding units, and to effectively troubleshoot problems in the field.

He has an extensive knowledge of rail grinding pattern design, pattern application, grinding templates, optimized grinding speeds, and various QA/QC functions that impact grinding efficiency and performance. He has served as a General Superintendent, Grind Superintendent, Maintenance Lead and Operator of Loram Grinding Machines – in addition to experience with Special Grinder Projects and Grinder Overhauls.

Casslynn Ennis

Work Experience

2021-2022: Summer Data Services Intern with Advanced Rail Management; 2022-present: Data Services Specialist with Advanced Rail Management /GRG

Education

Mechanical Engineering Technology (2022) – Red River College

Languages

English, French (minimal)

Henry Kweens

Henry has 20 years professional experience with proprietary rail recognition software and on-rail specialized data collection. He is responsible for training of new team members and joined ARM/Global Rail Group in March 2003.

Shane Kweens

Shane has been involved in data collection, data processing and analysis of various data types for the past 20 years with ARM/Global Rail Group. He uses this information to support railroad maintenance managers and internal grinding staff in planning corrective and preventive rail maintenance. He is also experienced in training internal and external clients on proprietary rail profile analysis software. Shane holds a Diploma in Business Administration and Marketing.

George Senterfitt III

Work Experience

Since July 2022

7 years

Advanced Rail Management – Rail Maintenance Specialist (2019-2021) & ( July 2022-Current)

Loram – Crew Chief (Oct. 2014 – Feb. 2019)

Education

Polk State College, Associate in Arts- Elementary Education (2011)

South Florida State College, Bachelor’s in Applied Science- Supervision and Management (July 2022-Current)

Languages

English

American Sign Language (ASL) – a little

Beatriz Alonso Vázquez

Work Experience

Since September 2023: Senior Consultant at Global Rail Consulting

2021-2023: Senior OCS Engineer at HS2 ltd.

2018-2021: Power and M&E Engineering Manager at Sener UK

Utilities Project Manager at Sener UK

2005-2017: Electrical Design Manager at Prointec S.A.

Electrical and Signalling Manager at Prointec S.A.

Assistant Project Manager at Prointec S.A.

2003-2005: Logistics Engineer at El Corte Ingles S.A.

Education

MSc industrial Engineering; ICAI- Universidad Pontificia de Comillas

Languages

Spanish

English

Alberto Pérez Carabias

Experience

Global Rail Group (March 2024 – Present): Solution Architect

Capitole (November 2023 – March 2024): Project Manager Data Tech Lead at Repsol

Wunderman Thompson MAP and Jellyfish (May 2021 – July 2023): Business Intelligence Senior Manager & Data Tech Lead regarding digital marketing solutions internationally.

Neoris, Zartis, Cognizant (May 2005 – April 2021): Business Intelligence & Data Tech Lead across different companies, projects, industries and technologies as a consultant.

Education

Técnico Superior Desarollo Aplicaciones Informáticas

Languages

English

Spanish